MIL-DTL-83196C(USAF)

3.

REQUIREMENTS

3.1

First article. When specified (see 6.2), a sample shall be subjected to first article

inspection in accordance with 4.2.

3.2

Materials.

3.2.1 Basic fabric. The basic integral fabric shall comprise of a layer of oriented, high loft,

continuous filament nylon yarns (nylon filler) sandwiched between linked layers of knitted cotton

(see figure 1). The color of the nylon fibers shall be white or natural. The color of the knitted

cotton shall be sage green and approximate USAF color shade No. 1509 (see 6.3). The nylon

yarns shall be introduced evenly and in sufficient numbers between the tie stitches of the two

layers of knitted cotton in such a manner that the length is in the direction of the greatest stretch

and to meet the required thickness over the full width of the fabric. The finished fabric shall

present a smooth (unpuckered) surface on both sides and shall conform to the requirements

specified in table I.

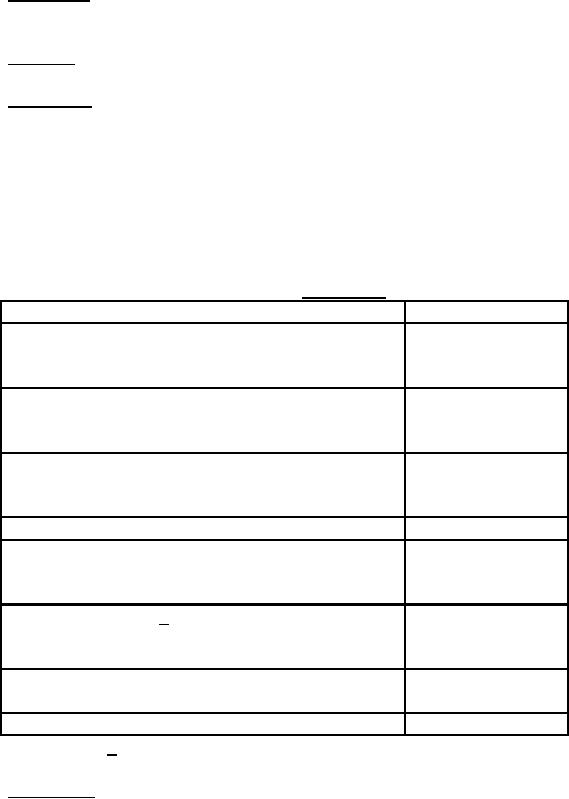

TABLE I. Basic fabric.

Characteristics

Requirement

Total weight, ounces per square yard

Minimum

20

Maximum

23

Knited cotton weight, ounces per square yard

Minimum

11

Maximum

12

Nylon filler weight, ounces per square yard

Minimum

9

Maximum

11

Thermal conductivity when compressed 25%

0.0474 to 0.0478

Thickness

Uncompressed, inch

0.25 ± 0.01

Compressed (percent of uncompressed), minimum

80

Elongation, percent 1/

Wales

35

Courses

70

Air permeability, cubic feet per square foot per

100

minute, minimum

Width, inches

32 ± 1

1/ Minimum stretch at 1/3 maximum tensile load.

3.2.1.1 Nylon yarns. The nylon filler shall be delustered nylon yarns. The nylon yarns before

crimping or texturing shall be 2 ply, 80 to 180 denier with a maximum filament size of 7 denier

per filament. The nylon yarn shall be one of the following types:

a.

A yarn with a pronounced crimp pattern of 4/64 ± 1/64 inch in height and 14 to 16

crimps per inch.

b.

A yarn, having a minimum elongation of 300%, in a random crimp pattern, a fiber

entanglement pattern, or a combination random crimp and fiber entanglement pattern.

4

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business