MIL-DTL-83196C(USAF)

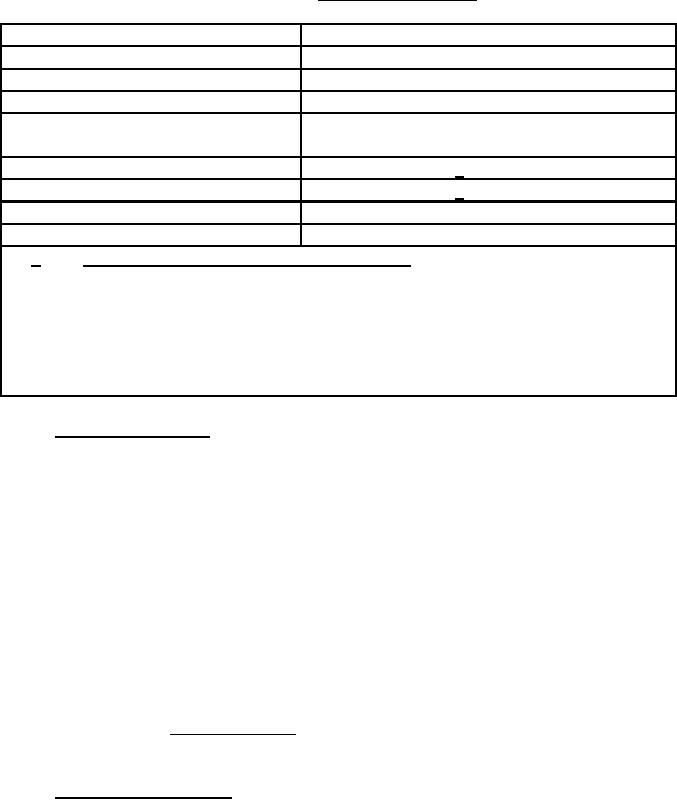

TABLE VI. Testing of basic fabric.

Characteristic (see table I)

Test Method

Total weight

ASTM D3776 (Option C)

Knitted cotton weight

ASTM D3776 (Option C)

Nylon filler weight

ASTM D3776 (Option C)

Thermal conductivity at 25

ASTM C177

percent compression

Thickness, uncompressed

ASTM D1777 1/

Thickness, compressed

ASTM D1777 1/

Elongation (finished fabric)

ASTM D5034

Air permeability

ASTM D737

1/

Woven and knitted materials, felts, nonwoven. A thickness gauge of the dead-

weight type, equipped with a dial graduated to read directly to .001 inches, shall

be used. The presser foot shall be circular, with a diameter of 1.129 +/- 0.001

inches and with moving parts weighted to a apply a total load of 0.60 +/- 0.03

pounds per square inch to the specimen. The anvil shall be not less than 1.129

inches in diameter. The presser foot and anvil surface shall be planed to within

0.0001 inches and shall be parallel to each other to within 0.0001 inches.

4.6.1 Weight determination. The test sample shall be a piece of the finished material and a

minimum of 4 square inches cleanly cut from the bulk of the material. No two samples shall be

taken from areas containing the same wales and courses. Five samples shall be tested from each

sample unit. An analytical balance capable of weighing to an accuracy of 0.01 gram shall be used.

The samples shall be preconditioned in accordance with section 4 of FED-STD-191. The three

layers of the sample (two layers of knitted cotton and one layer of nylon filler) shall be separated

by cutting the tie stitches midway between the two cotton layers. After the layers have been

separated, the cotton layers and the filler layer shall be weighed separately. The total weight of

the two layers of cotton shall be considered as the weight of the knitted cotton for one sample and

the weight of the filler shall be considered as the weight of the filler for one sample. The weight

of the knitted cotton and the weight of the filler shall be added together to determine the total

weight of the fabric in ounces per square yard. The weight of the sample unit, calculated as

shown in equation (1), shall be the average of the results obtained from the samples tested.

(1) Weight (oz/yd2) = Weight of sample

Area of sample

4.6.2 Elongation (nylon yarns). A scale graduated in inches and fractions of an inch and of

sufficient length to determine the maximum elongation shall be employed. A single yarn strand,

minimum length of 3 inches and in a relaxed state, shall be placed along the length of the scale

with one end of the strand at the end of the scale. The end of the strand at the end of the scale

shall be held in a fixed position with one hand, and the opposite end of the strand shall be moved

along the scale to the maximum extent that can be exerted by hand tension only. The length

reached shall be recorded to the nearest 1/8 inch. The elongation percentage shall be calculated

from the relaxed and the elongated dimensions. The average of the three tests results shall be

considered the elongation percentage.

12

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business