MIL-DTL-81905G(AS)

anti-G garment, the pull tape for the slide fasteners, the loops for the slide fasteners, and the

hanger shall conform to NCTRF PD 01-10, type II. Class designation will be identified as per

contract. Test method 5556.1 of FED-STD-191 shall be replaced with AATCC 135

Type V, A iii utilizing 5 wash cycles. Class I will be U.S. Navy shade sage green 3734, and

Class II will be U.S. Navy shade Khaki P1 3729.

3.4.1.2 Polyurethane coated nylon cloth. The material for the bladder (including the

attachment patches) and reinforcement of the inflation external tube covering shall conform

to MIL-C-83489, type I, except the finished weight shall be 5.50 to 6.75 ounces per square yard,

and the minimum tear strength shall be 5 pounds in the warp direction and 4 pounds in the fill

direction.

3.4.2 Reinforcements and bindings. Unless otherwise specified herein, the reinforcements

shall be made of the basic fabric specified in 3.4.1.1. The bias binding shall be 45 degrees bias

cut 1¼ inches to 1½ inches wide from the basic fabric specified in 3.4.1.1.

3.4.3 Spacer material. The spacer material for the bladder and spacer tube of the bladder

inflation hose shall conform to MIL-C-43204, type III. (see 6.6).

3.4.4 Adjustment laces and lanyard. The cord for the lanyard and for the adjustment laces

shall conform to MIL-C-83242, type I and table I and shall approximately match the shade of the

basic material in 3.4.1.1.

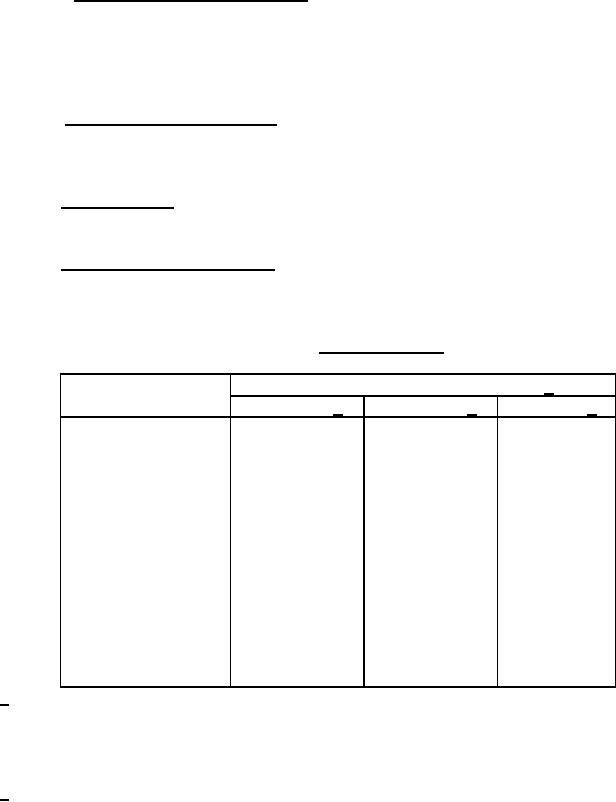

TABLE I.

Adjustment laces.

Size of anti-G

Length of Adjustment Laces (Feet) 1/

Garment

Waist Area 2/

Thigh Area 2/

Calf Area 2/

Small Regular

12

12

14

Small Long

12

13

16

Medium Regular

12

13

16

Medium Long

12

14

17

Large Regular

13

14

17

Large Long

13

16

19

Large Extra Long

13

16

19

1/ Dimensions are approximate and shall be governed by the following requirement: Both ends of each

adjustment lace shall extend at least 6 inches beyond the open end of the lacing tape when the

adjustment laces are completely extended. Both ends of each adjustment lace shall be dipped in a hot

solution of 50 percent beeswax and 50 percent paraffin.

2/ Two per anti-G garment shall be required.

6

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business