MIL-DTL-87174A(USAF)

a.

Inprocess examination (see 4.5.3).

b.

Visual examination of molded, unpainted shell (see 4.5.3.1).

c.

Visual examination of painted shell prior to installation of edgeroll (see 4.5.3.2).

d.

End-item visual examination (see 4.5.4).

4.4.2 Sampling plans. Unless otherwise specified, sampling plans shall conform to an accepted

commercial sampling standard (see 6.2 and 6.8).

4.4.2.1 Sampling plan A. The items specified in table III shall be subjected to the dimensional

examination of 4.5.2.

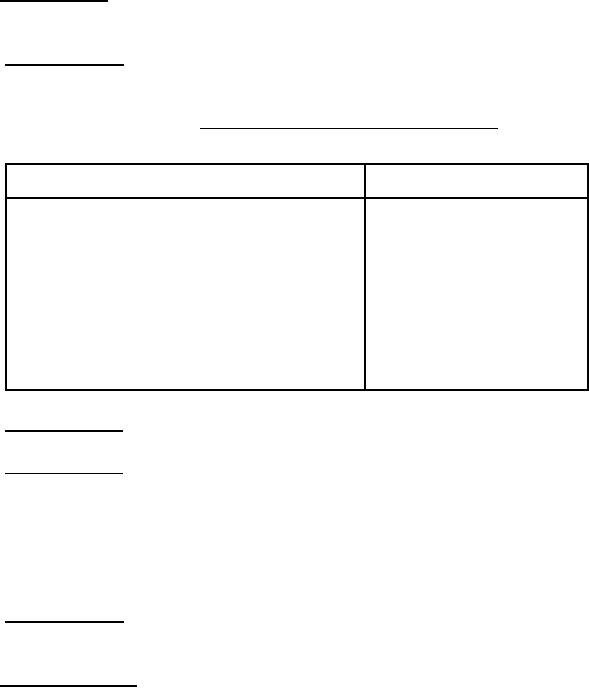

TABLE III. Sample unit for dimensional examinations.

Component

Sample Unit

Molded shell, unpainted

1

Chin strap assembly

1

Nape strap assembly

1

Pad set, fitting, earcup

1

Absorbent liner, each size

1

Visor lenses - MBU-12/P (Neutral Gray)

1

Bayonet receiver kit

1

Lens cover

1

Lens bag

1

4.4.2.2 Sampling plan B. The items listed in 4.5.3.3 shall be subjected to visual examination.

4.4.2.3 Sampling plan C. Helmet assemblies from each lot shall be subject to the following tests.

a.

Shell finish adhesion (see 4.5.5)

b.

Heat exposure (see 4.5.6)

c.

Penetration resistance (see 4.5.7)

d.

Impact protection (see 4.5.8).

4.4.2.4 Sampling plan D. Helmet assemblies of each size, assembled in accordance with 3.9 shall

be taken from each lot and subjected to examination for the weight as specified in 3.8.

4.4.3 Common hardware. The common hardware such as screws, nuts, washers, eyelets, and

grommets used in the fabrication and assembly of the helmet shell components shall be inspected

in accordance with their applicable drawings and specifications.

10

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business